- #Aircraft magneto overhaul serial

- #Aircraft magneto overhaul manual

- #Aircraft magneto overhaul Patch

Aircraft Spruce also has the special tools you will need to work on your Slick magneto, but they can be hard to find if you don’t have the part numbers. We’ll start with a discussion of Slick mags, the most common.Īircraft Spruce sells overhauled magnetos on an exchange basis with work performed by Kelly Aerospace or Champion (Slick), or you can go to an independent shop such as Aero Accessories in Torrance, California, for a more economical solution. Some of this work you can do yourself, but some of what may be needed is beyond most owners’ ability. Lag should be equal to the recommended spark advance on the engine data plate.Ībout every 500 hours, your magnetos need to be inspected and repaired as needed (IRAN) to keep them performing well.

#Aircraft magneto overhaul serial

There is an interesting discussion of this screw and the problems associated with installing it that I highly recommend be read by anyone working on this magneto.The data plate on the side of the magneto will tell you the serial number, model number, the direction of rotation and the lag of the impulse coupling.

#Aircraft magneto overhaul manual

Personally, if the mechanic did not have the maintenance manual for the D3000 in hand I would not let him touch the magneto.

Follow the factory instructions - accept no deviation or alternative methods of compliance.Ĭontinental (Bendix) has addressed each one of these areas in their maintenance manual.

Continental says to replace it with a new one. The locking effectiveness is poor if re-used.

#Aircraft magneto overhaul Patch

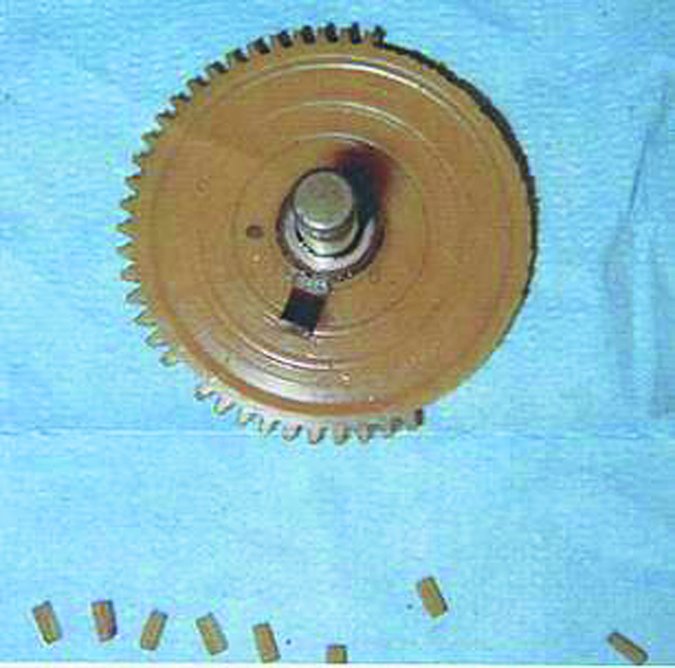

This screw is a self-locking screw that uses a nylon patch on the threads. You loosen this screw when you adjust internal timing. The problem here is that the mechanic did not order a new cam screw and re-used the old one. The investigation did show, that the screw (Fig 1-14 D-3000 Magneto manual ) was loose and so the cam breaker could turn on the cone. The following ground check did show no problems: rpm drop 70-80 rpm max rpm 2320 rpm.Īfter this the aircraft made a take off and crashed immediately in the ground, as the engine lost power. The air intake filter was dirty and cleaned. The timing of the ignitions examined and adjusted. The intake tube of the Cylinder No 3 was leaky -it was renewed. Here is a copy of an email I received some time ago from Germany:Ī pilot came to an aircraft workshop with the problem,that the engine did not start well and did not reach more the 2200 RPM. Personally, if I lived in a corrosive area I would replace it every year.Ĭam Retaining Screw: "Everything hangs on this connection" With two magnetos you lose timing but you can turn the bad magneto off with the D3000 magneto the broken spring retards the timing on both magnetos and you lose power.įollow TCM's instructions and recommendations to the letter in regards to inspecting and replacing the impulse spring. The impulse spring gets tiny rust pits that create stress corrosion cracking. On any magneto the impulse area sometimes gets rusty from condensation. Cessna 172N N738BC ditched at sea with 2 fatalities.

Follow the maintenance/overhaul manual, service bulletins and airworthiness directives. The D3000 magneto is a good magneto, easy to work on and reliable. About the only parts that are truly redundant is the coil, points, and capacitor. Yes, the maintenance/overhaul manual for this magneto. My question regards redundancy: what internal elements are common to the two magnetos within the D housing?ĭo they only share a common drive shaft (and gear), or are any other electromechanical components shared - e.g., cam, magnets, etc.? Do you know of any source where I could see internal photos or mechanical or cutaway drawings of the D3000 magneto so I could better understand its design? Our Cardinal has the dual magneto, although I am considering a conversion to a non-D at the upcoming overhaul. After reading the book, I do have two questions I'm wondering if you could answer given your experience with magnetos.ġ. John, I purchased and read your magneto book, which I found informative and interesting.

0 kommentar(er)

0 kommentar(er)